What is an Application Process Review?

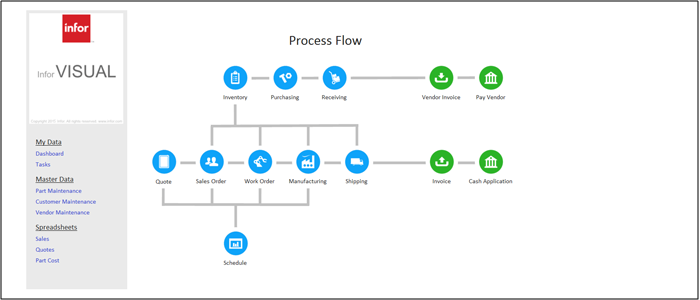

What we do in an Application Process Review (APR) is pretty straightforward, and we perform several for our clients over the course of a typical year. In the review, we observe how the ERP processes have been built to manage the business. Then, we make recommendations to streamline and improve the processes and procedures related to the flow of data in the company. For example, how to use the ERP to alert procurement of projected material shortages, as opposed to having them look for shortages in a spreadsheet – usually after it was manually updated. In essence, an ERP application process review is a gut check on how things are working, and what can be done to make them better.